Known for low density, high strength, corrosion resistance and conductive properties, titanium metal and titanium alloys are up to 45% lighter than steel of comparable strength and twice as strong as aluminum, copper or brass. These benefits are weighed against the cost and difficulty of acquiring and processing this extremely hard substance. Read More…

All Titanium Metals is a leader in the titanium industry, embodying a commitment to excellence as your trusted titanium supplier. In our unwavering pursuit of providing top-notch commercially pure-grade titanium products, we take immense pride in our high quality products.

Service Steel Aerospace (SSA) is one of the largest titanium distributors in the World. SSA stocks titanium rounds, plate, block, billet, and ingot for the Aerospace and Defense markets, as well as other critical industries. We rely on our vast inventory to offer quick deliveries. SSA places the highest value on quality and customer service. SSA also offers value added processing such as cut to...

At Cada Stainless & Alloys, we specialize in supplying high-performance titanium and specialty metal solutions for industries that demand exceptional strength, corrosion resistance, and long-term reliability. We work closely with customers who require titanium materials for challenging environments, including aerospace, chemical processing, marine, medical, and advanced industrial applications.

At Tri-Tech Metals, we specialize in delivering high-quality stainless steel to meet the demanding needs of industries across the country. We take pride in offering an extensive selection of stainless steel grades, sizes, and finishes, ensuring that our customers always have the right materials for their projects. By leveraging our expertise and advanced processing capabilities, we provide...

At TMS Titanium, we present ourselves as a specialized supplier and processor of titanium materials built to support demanding applications where strength, corrosion resistance, and reliability are essential. We focus exclusively on titanium, providing customers with access to high-quality material that meets strict mechanical and chemical requirements.

At Universal Metals, we present ourselves as a trusted supplier of titanium materials dedicated to supporting applications where strength, corrosion resistance, and performance consistency are critical. We work with high-quality titanium grades selected to meet demanding mechanical and chemical requirements, providing material solutions that perform reliably in challenging environments.

More Titanium Foil Suppliers

Titanium Foil: Properties, Applications, and Industry Insights

Titanium foil is a highly specialized material prized for its exceptional ductility, corrosion resistance, and remarkable strength-to-weight ratio. The forming of foils, however, is a pre-process that adds ductility to the long list of desirable attributes of the materials and renders titanium easily fabricated. This unique combination of properties allows for the widespread use of titanium foil across diverse industries, including machine building, aerospace engineering, aircraft manufacturing, marine shipping, mass transit, automotive, sports equipment, medical devices, and power generation.

What Is Titanium Foil?

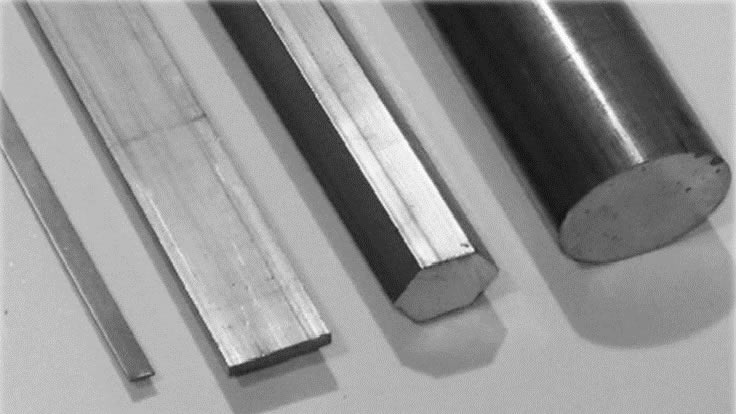

Titanium foil refers to thin sheets of titanium, typically with a thickness ranging from as little as 0.001" up to 0.009". It is produced in a variety of grades and alloys to meet specific requirements for strength, flexibility, and chemical resistance. The ultra-thin nature of titanium foil makes it an ideal material for applications where lightweight, high-performance, and corrosion-resistant solutions are required.

How Is Titanium Foil Manufactured?

Foil is used both in the creation of final products as well as in finishing, as it is easily molded and adheres to pre-existing forms for added protection, strength, and resistance to corrosive materials and environmental wear. Generally available in rolled coils, many manufacturers prefer to buy titanium in this stock form as it is regulated and allows for predictable shipping and processing requirements. Common processes used to create titanium foils include continuous cast stripping, rolling, and pressing of cast ingots.

The production of titanium foil necessitates the extraction of titanium from mineral deposits, most often utilizing the Kroll Method. This involves forming titanium tetrachloride through fractional distillation. The substance is then reduced to usable metallic titanium using magnesium. The resulting highly porous yield is referred to as a sponge. Foils are formed when this sponge, or bulk, is melted and then pressed, rolled, and cut into predetermined or customized titanium sheets which are sold by the square inch or square foot. Used in such varied applications as capacitor and converter foils, camera shutters, and wind screens, foils offer a wide range of thickness.

Titanium Foil Thickness and Grades

Titanium can be pressed as thin as 0.001". Thicker foils can be up to 0.009" thick, but thicker qualifies as a sheet or titanium plate rather than a foil. Titanium foils are produced using either raw materials provided by the customer or using the mill's own resources. Some mills will not manufacture foils from outside titanium sources without grade certification and mechanical property testing to ensure that they are outfitted with the proper equipment. Titanium grade is a significant consideration for manufacturers as processing high-purity titanium is extremely energy intensive and ductility varies among the many grades.

Key Properties and Benefits of Titanium Foil

- Corrosion Resistance: Titanium foil naturally forms a protective oxide layer, making it extremely resistant to corrosion by seawater, acids, and industrial chemicals. This property makes it ideal for chemical processing, marine, and medical applications.

- High Strength-to-Weight Ratio: Titanium is as strong as some steels but much lighter, enabling significant weight savings in aerospace, automotive, and sporting goods manufacturing.

- Biocompatibility: Titanium foil is non-toxic and highly compatible with biological tissues, making it suitable for use in medical implants, surgical instruments, and dental devices.

- Ductility and Formability: The foil form can be easily shaped, stamped, or pressed into complex shapes, supporting advanced manufacturing processes such as deep drawing and precision stamping.

- Thermal Stability: Titanium retains its mechanical properties at both extremely high and low temperatures, making it valuable for aerospace, power generation, and cryogenic applications.

- Electrical Conductivity: While not as conductive as copper or aluminum, titanium foil is used in specialized electrical and electronic applications such as capacitor and converter foils due to its unique balance of conductivity and stability.

Common Applications of Titanium Foil

Looking for ideas on how titanium foil is used in industry? Here are some of the most common and innovative applications:

- Aerospace and Defense: Used in thermal insulation, honeycomb structures, and lightweight shielding components for satellites, aircraft, and spacecraft.

- Medical Devices: Essential for pacemaker cases, hearing aid components, surgical instruments, and dental foils due to its biocompatibility and corrosion resistance.

- Automotive and Motorsport: Applied in heat shields, exhaust components, and racing vehicle parts to reduce weight and improve efficiency.

- Electronics: Utilized in the production of capacitor foils, battery electrodes, and EMI (electromagnetic interference) shielding for sensitive electronic equipment.

- Industrial Processing: Used as a liner or cladding in chemical processing equipment, reactors, and piping to protect against aggressive chemicals.

- Energy and Power Generation: Employed in fuel cells, solar panels, and nuclear power systems where high strength, corrosion resistance, and thermal stability are essential.

- Consumer Products: Found in sports equipment, high-end watches, and even luxury goods due to its premium appearance and durability.

- Scientific Research: Used in laboratory equipment, X-ray windows, and vacuum chamber linings for high-purity environments.

How to Select the Right Titanium Foil: Key Decision Factors

When researching and purchasing titanium foil for your specific needs, several important decision factors should be considered to ensure optimal performance and cost-effectiveness:

- Grade Selection: Titanium is available in commercially pure grades (such as Grade 1 and 2) for high ductility and corrosion resistance, and alloyed grades (like Grade 5/Ti-6Al-4V) for higher strength and temperature resistance. What grade of titanium foil suits your application best?

- Thickness & Width: Determine the required thickness and width for your project. Custom slitting and cutting services are often available from titanium foil suppliers.

- Surface Finish: Foil can be supplied with various finishes, from bright annealed to matte or etched, depending on aesthetic or functional needs.

- Certifications & Traceability: For critical applications, especially in aerospace and medical fields, ensure the supplier provides full material certifications and traceability to origin.

- Volume and Packaging: Consider whether you need small samples, bulk coil, or custom-cut pieces. Proper packaging is important to prevent contamination or damage during shipping and storage.

- Supplier Reputation: Work with reputable titanium foil manufacturers or distributors who can provide reliable lead times, quality assurance, and technical support.

Comparing Titanium Foil to Other Metal Foils: Why Choose Titanium?

How does titanium foil compare to aluminum foil, stainless steel foil, or copper foil? Titanium stands out due to its unmatched resistance to corrosion, superior strength-to-weight ratio, and excellent biocompatibility. While aluminum foil is more conductive and copper foil is more malleable, neither matches titanium's performance in harsh environments or critical medical and aerospace applications. Stainless steel foil, though strong, is heavier and less resistant to certain chemicals than titanium foil.

Industry Use Cases: Real-World Applications for Titanium Foil

Seeking inspiration for your next project or looking to justify a material spec change? Explore these real-world examples of how titanium foil delivers value:

- Satellite Thermal Shields: Thin titanium foil layers protect delicate satellite electronics from extreme temperature fluctuations in space.

- Fuel Cell Components: In hydrogen fuel cells, titanium foil serves as a corrosion-resistant, lightweight electrode material, boosting efficiency and lifespan.

- Implantable Medical Devices: Pacemaker housings and surgical mesh benefit from titanium's biocompatibility, reducing the risk of rejection and infection.

- High-Performance Exhaust Systems: Racing teams use titanium foil as a heat barrier and liner to reduce weight and improve thermal management.

- Battery Technology: Lithium-ion battery manufacturers use titanium foil as a current collector and separator in next-generation batteries.

- Chemical Process Equipment: Titanium foil linings in reactors and piping extend service life and minimize maintenance in harsh chemical processing environments.

Top Benefits of Sourcing Titanium Foil for Your Application

When you choose titanium foil for your industrial, medical, or consumer product, you unlock a host of performance, cost, and sustainability advantages:

- Long-Term Durability: The combination of corrosion resistance and mechanical strength ensures a long service life, even in aggressive environments.

- Reduced Maintenance: Titanium’s resistance to scale, pitting, and chemical attack minimizes downtime and lowers total cost of ownership.

- Lightweight Efficiency: Save weight without sacrificing performance—critical for aerospace, automotive, and portable electronics.

- Sustainability: Titanium is fully recyclable and often sourced from recycled material, supporting greener supply chains.

- Design Flexibility: Available in custom thicknesses, widths, and surface treatments to meet exacting design specifications.

- Regulatory Compliance: Medical and aerospace-grade titanium foil can be sourced with full certifications to meet FDA, ASTM, or AMS standards.

Frequently Asked Questions (FAQ) About Titanium Foil

- What is the minimum order quantity for titanium foil?

Minimum order quantities can vary by supplier and grade, with some offering small sample sizes for R&D and prototyping. - How is titanium foil delivered?

Typically, titanium foil is shipped in tightly wound coils, sheets, or custom-cut pieces, with protective packaging to prevent contamination and physical damage. - Can titanium foil be welded or soldered?

Yes, but specialized techniques are required due to titanium’s affinity for oxygen and nitrogen at high temperatures. Laser welding, electron beam welding, and inert gas environments are commonly used. - Is titanium foil magnetic?

No, titanium is a non-magnetic material, which is advantageous in sensitive electronic and medical applications. - What are the main standards for titanium foil?

Common standards include ASTM B265 for titanium strip, sheet, and plate, and AMS 4911 for aerospace applications. Always confirm material grades and certifications with your supplier.

How to Find the Right Titanium Foil Supplier

Ready to purchase titanium foil for your business or project? Here are some action-driven tips to identify the best titanium foil manufacturer or distributor:

- Search for suppliers with a track record in your industry—look for case studies, client testimonials, and ISO certifications.

- Request material samples and technical datasheets to evaluate quality and suitability for your application.

- Ask about customization options, including thickness, coil size, surface finish, and packaging.

- Verify supply chain transparency, traceability, and compliance with industry standards.

- Assess supplier capability for fast delivery, technical support, and ongoing service.

Explore Further: Related Titanium Materials and Solutions

If your application requires thicker or differently processed titanium materials, consider exploring other titanium product forms:

- Titanium Sheet: For applications needing thicker, more rigid material.

- Titanium Plate: Selected for heavy-duty and load-bearing uses.

- Titanium Bar: Ideal for machined components and structural parts.

- Titanium Tubing: Used in fluid transfer, medical devices, and lightweight frames.

- Titanium Wire: Preferred for precision springs, fasteners, and electrical contacts.

Ready to Source High-Quality Titanium Foil?

Whether you are an engineer, purchasing manager, or R&D professional, sourcing the right titanium foil can have a significant impact on your product’s performance and reliability. Evaluate your application’s demands, consult with leading titanium foil manufacturers, and leverage the unique properties of titanium to achieve your project goals.

Have questions about titanium foil grades, pricing, or availability?

Start your search today by connecting with proven titanium foil suppliers and requesting a quote tailored to your needs. Take advantage of technical support, material samples, and expert advice to make an informed decision for your next application.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services