The use of titanium in piping offers superior strength, rigidity, resistance to corrosion and lightness as compared to alternative metals. Read More…

All Titanium Metals is a leader in the titanium industry, embodying a commitment to excellence as your trusted titanium supplier. In our unwavering pursuit of providing top-notch commercially pure-grade titanium products, we take immense pride in our high quality products.

Service Steel Aerospace (SSA) is one of the largest titanium distributors in the World. SSA stocks titanium rounds, plate, block, billet, and ingot for the Aerospace and Defense markets, as well as other critical industries. We rely on our vast inventory to offer quick deliveries. SSA places the highest value on quality and customer service. SSA also offers value added processing such as cut to...

At Cada Stainless & Alloys, we specialize in supplying high-performance titanium and specialty metal solutions for industries that demand exceptional strength, corrosion resistance, and long-term reliability. We work closely with customers who require titanium materials for challenging environments, including aerospace, chemical processing, marine, medical, and advanced industrial applications.

At Sierra Alloys, we have built our reputation around the strength, versatility, and precision of titanium. We dedicate ourselves to delivering high-quality titanium products that serve industries where performance, durability, and reliability are non-negotiable.

At Tricor Metals, we have built our reputation as a trusted partner in titanium products and solutions by combining material expertise with advanced fabrication capabilities. We work closely with customers across demanding industries to deliver titanium that meets exacting performance, durability, and safety standards.

At Reliable Source Inc., we have built our reputation on being a dependable partner for customers who require precision titanium products and expert support for critical applications. From the start, we have focused on combining material expertise with an unwavering commitment to quality, allowing us to deliver titanium solutions that perform under the most demanding conditions.

Diversified Industrial Products is a leading distributor of high-quality titanium tubing, titanium wire, titanium plate, titanium bars and titanium ingots. We serve a wide range of industries and markets with high-quality, durable titanium. Diversified Industrial has more than 25 years of experience.

More Titanium Pipe Suppliers

Pipes constructed of titanium metal and titanium alloys offer twice the strength of copper, steel and aluminum with only 50% of the material volume. This low density material offers spatial savings significant to plumbing, flow tube and exhaust environments where space is often limited. These benefits outweigh the elevated initial cost of titanium which is a direct result of the processes necessary to extract it from ores such as Rutile and Ilmenite.

Military, marine, petrochemical, chemical and food processing, medical, automotive, transit, aerospace, agricultural, construction, electrical and paper and pulp industries all utilize titanium pipes in a number of applications such as heat exchangers, handrails and high end automotive fuel lines. The extreme tolerance for corrosive materials of this particular type of metal reduces the potential risk of dangerous line corrosion, valve breakages and leaks in industries where volatile chemicals are processed. The resilience of titanium likewise reduces maintenance while extending product longevity.

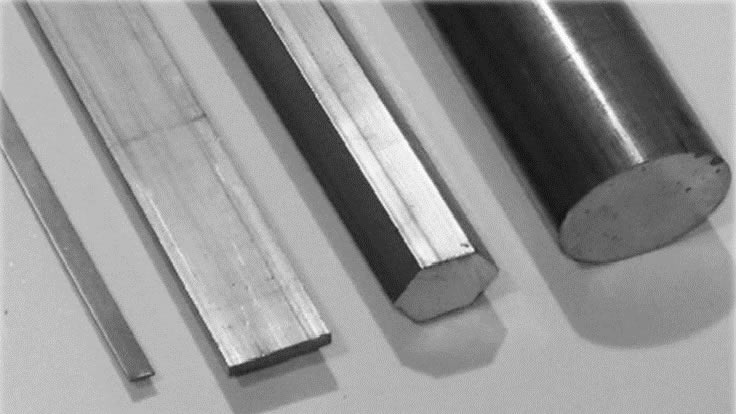

Pipe manufacturers buy titanium that has been pre-processed, making it suitable for secondary fabrication. While a variety of stock shapes are available, titanium sheets are the most applicable to pipe construction. These sheets are formed into long hollow tubes, which may have round, oval, square or rectangular cross sections. Extrusion, cold drawing or rolling and welding processes yield these structures. The intended use must be taken into consideration before selecting a particular technique. Welding, for example leaves a seam along the edge of the pipe that would not be suitable for some applications. The pipes are then processed to fit specific product demands and requirements.

Cutting, for example, is needed to ensure proper and standard pipe lengths. Bending, flaring and swaging are additional processes in titanium pipe manufacturing. The variable processing methods require a great deal of consideration with regards to the intended goal of a piece of piping. Additional considerations include the maximum pressure and temperature range, flexibility, optional lining and plating, interior diameter and shell thickness of titanium piping. The titanium grade should also be one of the most important considerations as these influence not only the mechanical and chemical qualities of the finished product, but also the necessary manufacturing methods which can be extremely energy intensive for purer titanium.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services