Titanium is a strong yet malleable metallic element that can be rolled cold or hot to produce titanium plates. Titanium has physical characteristics ideal for aeronautical engineering, dentistry, and construction. Read More…

All Titanium Metals is a leader in the titanium industry, embodying a commitment to excellence as your trusted titanium supplier. In our unwavering pursuit of providing top-notch commercially pure-grade titanium products, we take immense pride in our high quality products.

Service Steel Aerospace (SSA) is one of the largest titanium distributors in the World. SSA stocks titanium rounds, plate, block, billet, and ingot for the Aerospace and Defense markets, as well as other critical industries. We rely on our vast inventory to offer quick deliveries. SSA places the highest value on quality and customer service. SSA also offers value added processing such as cut to...

At Cada Stainless & Alloys, we specialize in supplying high-performance titanium and specialty metal solutions for industries that demand exceptional strength, corrosion resistance, and long-term reliability. We work closely with customers who require titanium materials for challenging environments, including aerospace, chemical processing, marine, medical, and advanced industrial applications.

At Sierra Alloys, we have built our reputation around the strength, versatility, and precision of titanium. We dedicate ourselves to delivering high-quality titanium products that serve industries where performance, durability, and reliability are non-negotiable.

At Tricor Metals, we have built our reputation as a trusted partner in titanium products and solutions by combining material expertise with advanced fabrication capabilities. We work closely with customers across demanding industries to deliver titanium that meets exacting performance, durability, and safety standards.

At Reliable Source Inc., we have built our reputation on being a dependable partner for customers who require precision titanium products and expert support for critical applications. From the start, we have focused on combining material expertise with an unwavering commitment to quality, allowing us to deliver titanium solutions that perform under the most demanding conditions.

Diversified Industrial Products is a leading distributor of high-quality titanium tubing, titanium wire, titanium plate, titanium bars and titanium ingots. We serve a wide range of industries and markets with high-quality, durable titanium. Diversified Industrial has more than 25 years of experience.

More Titanium Plate Suppliers

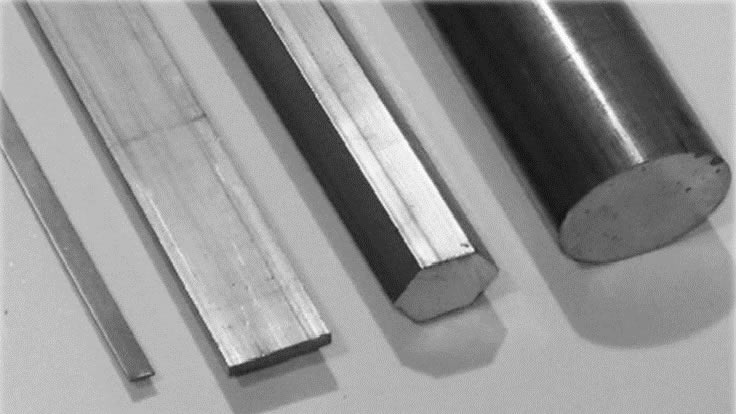

Titanium plates are lighter and have a weight-to-strength ratio of 1.7 times that of steel plates. Aluminum, manganese, iron, and molybdenum can improve the strength of titanium alloys. Titanium is a non-oxidizing metal that can withstand a variety of conditions.

The Kroll Process

The Kroll process is used to make titanium plates from raw titanium material.

In the industrial-scale Kroll method, titanium dioxide and chlorine react to create titanium tetrachloride at 800-850 °C in a stainless-steel retort. The titanium tetrachloride is reacted with magnesium to remove the chlorine, leaving behind the pure metal. Leaching or vacuum distillation purifies the porous, metallic titanium sponge. The sponge is compressed, crushed, and melted in a consumable carbon electrode vacuum arc furnace. Under vacuum, the molten ingot is allowed to harden. Titanium is frequently remelted To get rid of inclusions and guarantee homogeneity.

To produce TiCl4, silicon, iron, aluminum, magnesium, and calcium impurities are eliminated using fractional distillation. Then, pure TiCl4 is reduced by molten magnesium between 1073 and 1173 K in an argon environment to create sponge titanium.

The titanium plates are then produced utilizing three different techniques, resulting in various forms and sizes. Hot rolling, cold rolling, and sintering are processes used to create titanium plates.

Hot Rolling Titanium Plates

The heated metal is passed between two rolls to flatten, extend, decrease the cross-sectional area, and achieve a consistent thickness. The titanium slabs are rolled into black coils of extremely precise thickness and shape. Then they are transformed into white coils by heat treatment, pickling, and finishing in the annealing and pickling facility. Hot rolling can increase ductility, formability, weldability, toughness, strength, vibration, and shock resistance.

Cold Rolling Titanium Plates

Hot rolling produces thinner metal strips with good surface quality. Titanium is run through rollers during the cold rolling process at temperatures lower than its recrystallization temperature. As a result, titanium's yield strength and hardness increase through compression and squeezing.

Applications for Titanium Plates

Titanium plates are used to produce goods for the automotive, biomedical, aerospace, and military industries. For example, many hospitals use titanium to create orthopedic devices or implants. In addition, many common items, including stopwatches, watches, dental braces, tennis rackets, and golf clubs, are made of titanium.

Numerous industries use titanium plates and sheets, including construction, aviation, the military, aerospace, dental prostheses, and orthotics. In addition, titanium plates offer a way to replace or repair bone. Because it is lightweight, robust, and corrosion-resistant, titanium plates and sheets are helpful for various sections of the human body. Titanium is also used for prosthetic joints, orthopedic implants, and bone replacements.

Advantages of Titanium Plates

Titanium plates have high strength, low thermal expansion, and extremely high melting points. They are known to be one of the metals with the strongest resistance to corrosion.

Disadvantages of Titanium Plates

Titanium plates frequently need to be removed once the healing process is complete because they can lead to stress shielding, which makes the bones brittle. The cost of titanium plates is roughly six times that of stainless-steel plates.

Choosing the Proper Titanium Plate Manufacturer

To make sure you have the most productive outcome when purchasing titanium plates from a titanium plate manufacturer, it is important to compare at least 4 to 5 companies using our list of titanium plate manufacturers. Each titanium plate manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each titanium plate business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple businesses with the same quote.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services